How Do You Know When to Start Working Concrete

How to Terminate Concrete

Techniques for making a smoothen, durable finish on a concrete surface.

![]() Fourth dimension

Fourth dimension

A full day

![]() Complexity

Complexity

Intermediate

![]() Cost

Cost

$51–100

Introduction

In this article, nosotros'll show you lot the tools and techniques you need to become a smooth, durable finish on concrete. Nosotros'll also tell you how to know when the concrete is ready for each phase of the finishing process. Whether you're pouring a modest slap of physical, like a pad for your garbage can, or a large slab for a patio, these DIY steps will guide y'all through the process.

Tools Required

Finishing concrete

Shut-up: Darby

A darby flattens the wet physical.

Shut upwards: Edging tool

An edging tool gives the physical a round edge.

Close-up: Groover

A groover makes joints in the concrete to control cracking.

Close-upwardly: Magnesium physical manus float

A float compacts the physical surface, giving it a smooth expect. Putting a smooth, durable cease on concrete is a skill you tin can but master with the proper gear up of tools and practise. Nosotros'll prove you lot the tools and how to use them for each step of the physical finishing process. And equally important, we'll assistance yous make up one's mind when the concrete is set up for the next finishing step.

Just yous really can't practice these techniques except on existent concrete. Then it's smart to start with a small project similar this garbage tin pad. When y'all get the hang of it, you tin movement up to a larger slab. But proceed in mind that finishing larger slabs (more about 100 sq. ft.) is trickier because the concrete may fix too fast.

In this article, we'll bear witness yous how to level the physical in the forms, round over the edges and make a progressively smoother finish. But we won't show how to build forms or fill them with concrete.

Each stride in the procedure requires a dissimilar tool. You tin can brand the screed (Photo 1) and darby (Photograph 2) from scraps of wood. The rest you'll have to rent or buy. You'll need a magnesium float ($15 to $25), an edger ($v to $20), a grooving tool ($x to $30) and a steel trowel ($eight to $40). Pros buy expensive top-quality tools that will stand up up to the rigors of daily use, only less expensive versions are bachelor at home centers and hardware stores and volition work fine for occasional home utilise.

Concrete is a blend of Portland cement, sand, aggregate (gravel) and water that harden when mixed. While at that place are additives that can ho-hum down or speed upwards the process, and special bagged mixes that set fast, in general, the speed of the process largely depends on the temperature and humidity.

Hot, dry atmospheric condition accelerates the hardening process, sometimes so much that it's nearly impossible to consummate all the finishing steps in time. Work while your projection is in shade if possible. On absurd days, y'all may spend a lot of time waiting for the concrete to attain the adjacent stage. That's why we can't requite you lot exact waiting times. But we'll show you how to tell when the concrete is ready for each finishing footstep.

Video: How to Pour a Concrete Slab

Project step-by-pace (8)

Stride 1

Screed and darby the concrete correct away

Screed the physical

Push or pull the screed board across the forms with a back-and-forth sawing motion. Shove concrete into low spots in front of the screed board. Repeat to remove excess concrete.

Form and Pour a Concrete Slab

Step ii

Darby the concrete

Sweep the darby beyond the concrete in overlapping arcs to flatten the surface, push downwardly lumps and fill voids. Lift the leading edge slightly but proceed the darby level with the surface. Make 2 passes.

How to Pour a Concrete Slab Successfully: 31 Tips

Step three

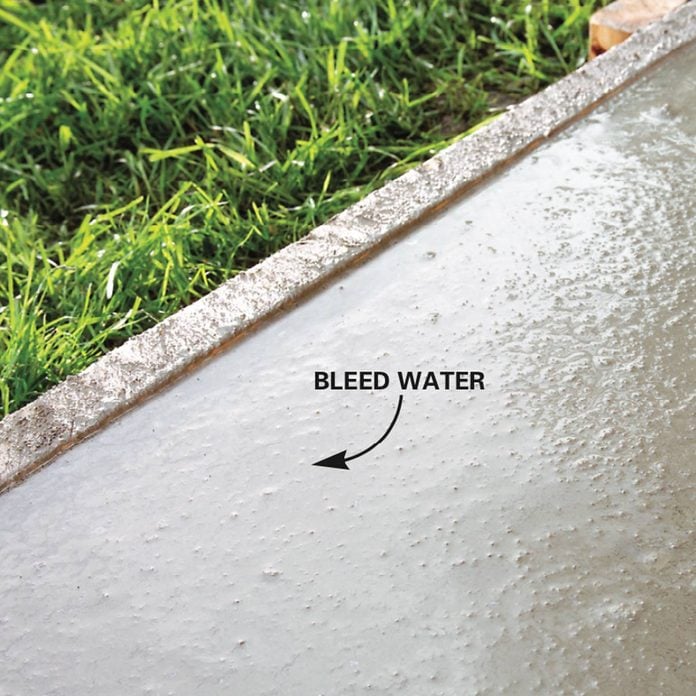

Wait for the surface water to disappear

Water volition announced on the surface. Wait until this "bleed" water and sheen disappear entirely before edging, jointing or floating the concrete. Screeding levels the concrete with the top of the forms and begins the process of forcing the larger aggregate beneath the surface. Use any 2x4 that overlaps the forms past at least 6 in., just make sure it'southward straight (Photo 1).

Follow screeding immediately with the darby (Photo two). Your goal is to level out marks and fill up minor holes left by screeding. In the process, you'll force larger aggregate downwardly, leaving a slurry of cement and sand to fill up the surface.

The darby should exist large enough to reach a little more than than halfway across the slab. Make a darby by screwing a handle (we cut a 2x4 with a jigsaw to make a handle) onto a straight piece of 1x4. Longer darbies may crave two handles for better control. If yous can't reach the entire slab from the edges with a darby, rent a bull float and handle to utilize instead. Two passes over the surface with the darby are enough. Overworking the concrete volition depict as well much cement and fine sand to the acme and create a weak surface.

Drilling Concrete and Installing Fasteners

Stride iv

Edge, groove and float the slab when the sheen is gone

Edge the physical

Work the edging tool dorsum and forth, using the edge of the form as a guide. Lift the leading edge slightly. Utilize long strokes, working the amass back until y'all accept smooth, round edges.

Step 5

Create grooves in the physical

Set a directly board along predetermined marks for control joints. Run the groover back and forth against the straightedge until the bed of the tool is riding on the concrete surface. Later smoothing the slab with the darby, water will "drain" out of the concrete and sit down on the surface (Photo 3). This is temporary. It'll soon reabsorb into the concrete. Nevertheless, it's critical to expect until it disappears.

Working the concrete before the surface "drain" water disappears volition weaken the surface of the slab when information technology dries. When all traces of the water are gone and the physical starts to harden, you can resume finishing activities. Test past pressing your gloved thumb onto the surface virtually the perimeter. The concrete is ready when pressing hard just leaves a ane/4-in. deep impression.

Start past running the edger around the perimeter to round and compact the corner (Photo 4). Sometimes it's a lilliputian tough at commencement equally you lot push larger aggregate back into the concrete and round over the edge. If the edger is leaving a path deeper than nearly one/8 in., await for the concrete to set a fiddling longer and employ less downwards pressure.

Adjacent divide the slab into equal parts with a straightedge and groover (Photograph 5). Sidewalks and modest slabs need grooves nearly every iv ft. Add together grooves every 10 or 12 ft. on driveways and garage slabs. Dividing slabs with grooves looks overnice, but the real reason is to control cracking. Drying and soil movement cause concrete to scissure. The groove creates a weakened spot for the crack to grade where it won't be seen. To be constructive, the groove must be at to the lowest degree one-4th the depth of the slab.

Footstep six

Float and trowel the surface to smooth and compact information technology

Bladder the concrete

Elevator the leading edge slightly while y'all sweep the magnesium concrete hand float over the concrete in large arcs to compact the surface. Blend in the marks left by the edges of the edger and groover.

How to Remove and Replace a Small Concrete Entry Pad

Step vii

Trowel the surface

Polish the surface with a steel trowel later on it's partially hardened. Hold the trowel about flat and swing information technology in big overlapping arcs while applying pressure. Float the concrete when yous're done grooving and edging (Photograph 6). Floating removes the marks left by edging and brings the surface one step closer to a final finish. You may have to deport down on the bladder if the concrete is starting to harden. Y'all'll be surprised that with plenty scrubbing you'll be able to bring a slurry to the surface of even a fairly difficult slab. If yous're happy with the look of your floated slab, you don't need to do any more finishing. Echo the edging and grooving steps after floating and later on troweling to refine the groove and edges. For a decorative border outcome similar to what's shown in the inset to Photograph 4, run the edger around each department of slab later a final broom terminate.

In Photo 7, we show how to put an even, smoothen terminate on the slab with a steel trowel. Troweling is one of the trickier steps in concrete finishing. Yous'll accept to practise to develop a feel for information technology. For a really smooth cease, repeat the troweling footstep two or 3 times, letting the concrete harden a bit between each laissez passer. At first, hold the trowel almost flat, elevating the leading edge just enough to avoid gouging the surface. On each successive pass, lift the leading edge of the trowel a fiddling more than. If y'all want a rougher, non-slip surface, y'all can skip this stride and do a broom finish (Photo 8). Besides, if yous guild air-entrained concrete delivered, don't trowel the surface.

How to Properly Mix Concrete

Footstep 8

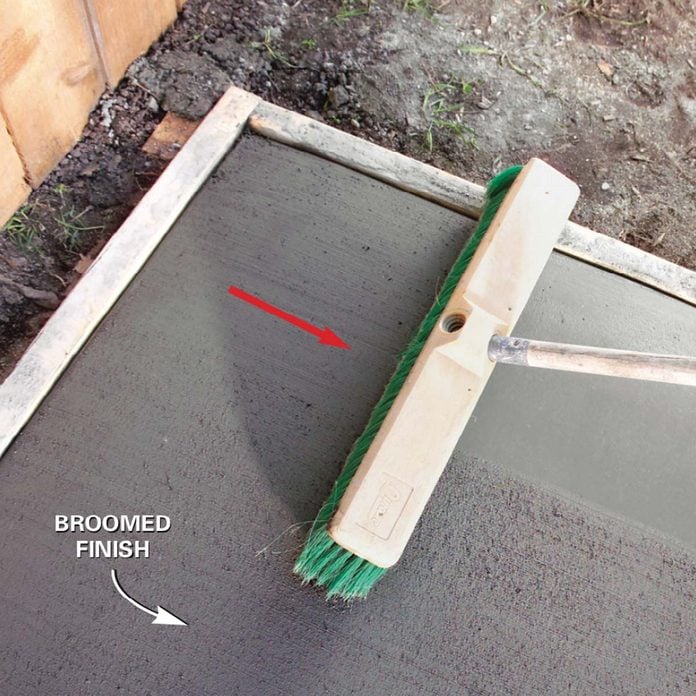

Broom finish for better footing

Create a not-slip surface

Drag a broom across the concrete after floating information technology with the magnesium float to create a non-slip surface. Adjust the downward pressure to create the desired amount of texture. Dragging a broom beyond partially hardened concrete leaves a rough texture that gives better traction in slippery conditions (Photo 8). Special concrete brooms are bachelor, but a regular button broom will work too.

Recall to launder off the bristles as soon every bit yous cease brooming physical. As with all the other finishing steps, the key to a successful broom finish is to wait until the concrete surface is just right. If concrete starts to pile upwards in front of the bristles every bit yous drag the broom across, resmooth the broomed area with a float or trowel and and so await a little longer before trying again.

When y'all're done finishing the physical, embrace it with plastic or keep it moist by sprinkling it several times a day for virtually a calendar week. This slows the curing process and results in a stronger, more than durable slab.

CAUTION!

It might exist hard to believe that concrete can be unsafe. But the potent alkalinity of cement can cause chemical burns but like a strong acid. Past the time you realize you're being burned, yous may already have skin damage. That's why it's essential to prevent prolonged skin exposure to wet concrete. And why yous should be extra careful to proceed moisture concrete from getting in your eyes. Wear rubber gloves, a long-sleeve shirt, long pants and condom glasses. Wear rubber boots if you'll be wading in concrete. Rinse moisture concrete from your skin immediately and remove clothes that accept become saturated with concrete.

Originally Published: September 24, 2019

Source: https://www.familyhandyman.com/project/how-to-finish-concrete/#:~:text=When%20all%20traces%20of%20the,a%201%2F4%2Din.

0 Response to "How Do You Know When to Start Working Concrete"

Post a Comment